The ball mills that Zhongke can provide include: rod mills, cement mill, raw material mill , ceramic ball mills, energy-saving ball mills, etc.ball mill grinder,ball mill rock crusher,ball mill for sale.

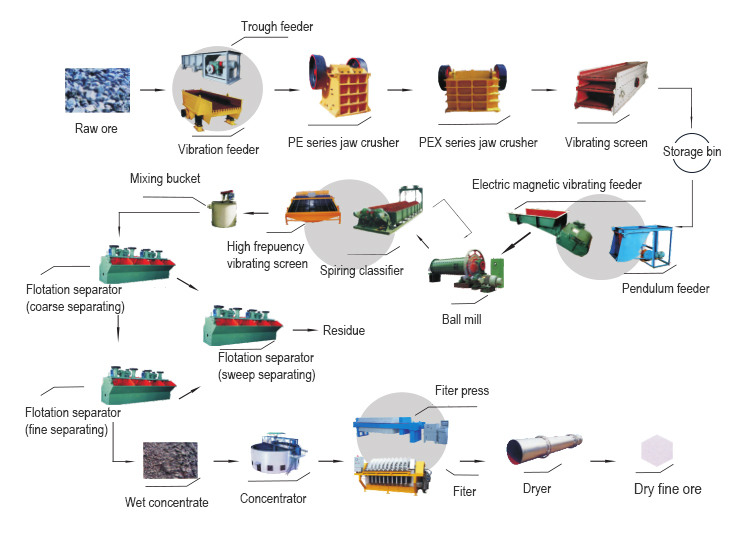

We can provide complete ball mill production line equipment. Ball mill is the key equipment for crushing the material after crushing, the capacity: 0.65-130T/H, 50-650T/H,etc. the discharge scope(mm): 0.074-0.89,etc.

Applicable materials: quartz, gold ore, iron ore, clinker, copper ore, magnetic pyrite, magnetite, etc., which are widely used in cement, building materials, construction and other industries.