A rotary kiln is a high-temperature thermal processing equipment used for calcination, pyrolysis, sintering, and material drying. It consists of a rotating cylindrical shell inclined slightly to facilitate material movement. Rotary kilns are widely used in industries such as cement production, lime manufacturing, waste incineration, and metal ore processing.

Rotary Kiln refers to rotating calcination kiln, belongs to construction material equipment. According to different materials, rotary kiln can be divided into cement kiln, metallurgy chemical kiln and lime kiln.

The cement kiln is used for makeing cement clinker and there are dry and wet methods to make cement. Metallurgy chemical kiln is applied in metallurgy industries and ironworks for lean iron ore, chromium ore and ferronickel ore calcination. Lime kiln is mainly used for calcine dolomite and active lime which is used in steel plant and ferroalloy factory.

Working Principle of Rotary Kiln:

1. With a certain slope to the level, the whole kiln body is supported by rollers and fitted with thrust rollers to control up and down movement of the kiln body.

2. Besides main driving unit for driving system, it is also fitted with the auxiliary driving unit so as to ensure the kiln body still can rotating when the main motor is powered off and prevent it from deforming.

3. The kiln head adopts housing type sealing and kiln rear uses axial contact sealing unit so that reliability of sealing could be ensured.

✅ High Thermal Efficiency – Advanced insulation & heat recovery systems reduce energy consumption.

✅ Customizable Design – Tailored for different materials, capacities, and temperature requirements.

✅ Durable Construction – Made from high-grade refractory materials for long service life.

✅ Automated Control System – Ensures precise temperature & rotation speed regulation.

✅ Eco-Friendly Operation – Low emissions & waste heat recovery options available.

Our rotary kilns are engineered for various industrial processes, including:

✔ Cement Production – Clinker calcination

✔ Lime Manufacturing – Quicklime & dolomite processing

✔ Waste Recycling – Incineration of hazardous & municipal waste

✔ Metallurgy – Roasting of iron ore, alumina, & other metals

✔ Chemical Industry – Processing of gypsum, phosphate, & catalysts

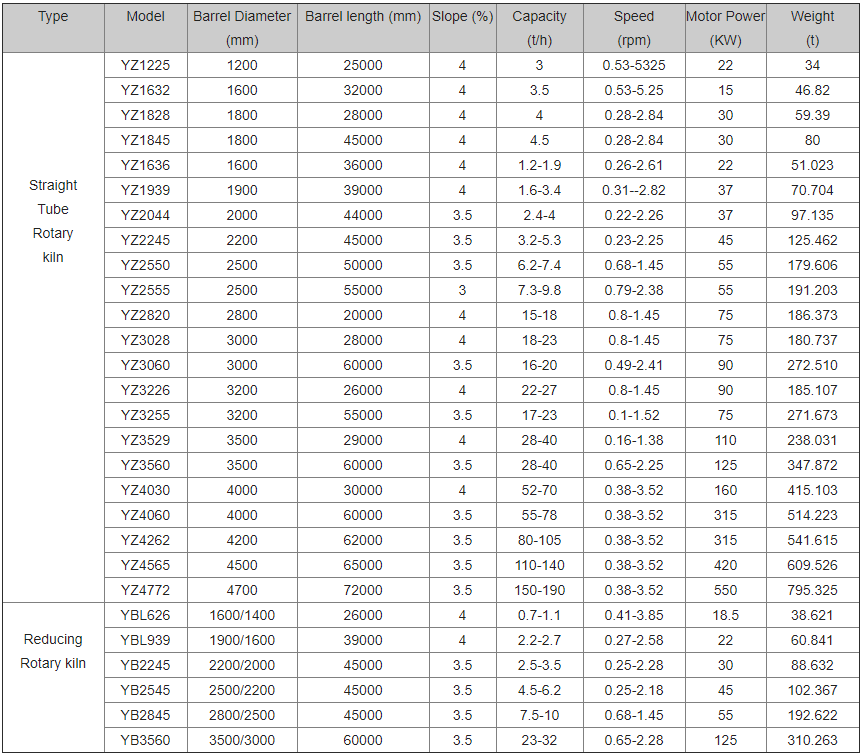

Main technical parameters:

🔹 Proven Technology – Trusted by leading global manufacturers.

🔹 Energy-Saving Solutions – Optimized combustion & heat transfer.

🔹 Low Maintenance – Robust design minimizes downtime.

🔹 Expert Support – Installation, training, and after-sales service.

We specialize in designing and manufacturing high-performance rotary kilns for diverse industrial needs. Contact us today for a free consultation and quote!