Complete beneficiation production line equipment includes: jaw hammer crusher, ball mill, classifier, magnetic separator, flotation machine, concentrator and rotary dryer and other main equipment, with the ore feeder, elevator, conveyor can form a complete beneficiation production line.we can formulate a complete solution according to your customer site.

Zhongke flotation machines are widely used in the roughing, beneficiation and reverse flotation of copper, lead, zinc, nickel, molybdenum and other non-ferrous metals, ferrous metals and non-metallic minerals, and can also be used for non-metallic such as: coal, fluorite, talc Sorting.

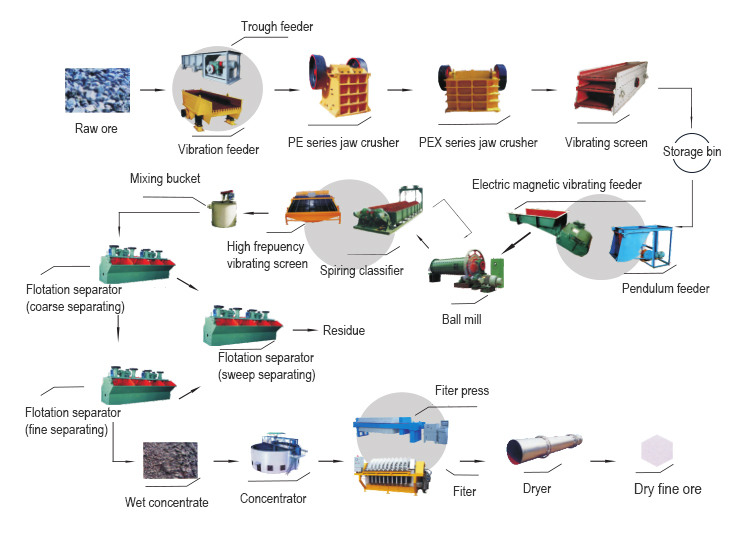

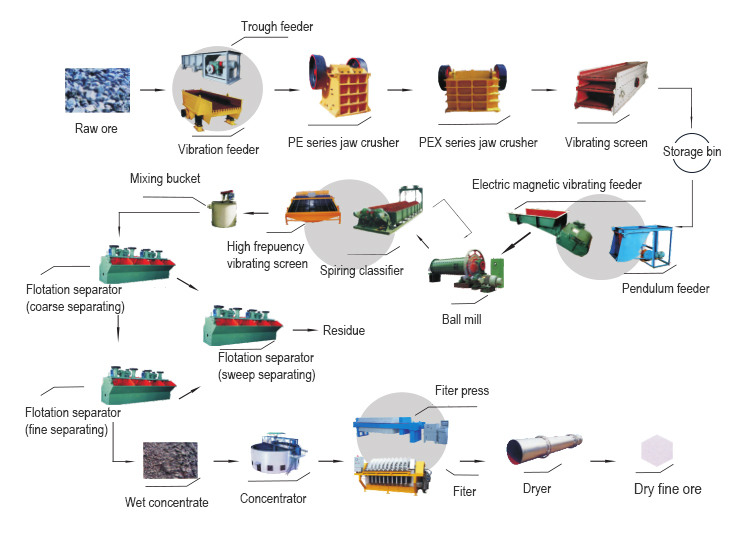

Process of flotation beneficiation:

1. Ore crushing;

2. The crushed material was sent to ball mill grinding;

3. Classified.Granule with unsuitable size will be sent back to the ball mill,while suitable ones will be sent to the flotation system;

4. Some medicament agent will be added to separate target material from others.

5. After going through the flotation system,they will be concentrated and filter pressed, and then get the final products;

6. The whole process is finished.

Advantages of Zhongke flotation beneficiation:

Zhongke has a strict and effective quality control syatem in manufacturing process.

Zhongke flotation beneficiation equipment have been approved by ISO9001-2008 &CE certification.

We not only supply the complete flotation bebeficiation with favorable prices,but also the installation and maintenance service for the customers.

We offer the service during the whole using-life of the equipment.

Model | Effective

volume (m³) | Processing

ability (m³/min) | Motor

power (kw) | Spindle

speed (r/min) | Scraper.

speed (r/min) | Scraper

power (kw) | Trough

size (mm) | Single slot

weight (kg) |

SF-0.37 | 0.37 | 0.2-0.4 | 1.5 | 352 | 25 | 1.1 | 700x700×750 | 468 |

SF-0.7 | 0.7 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | 900×820×950 | 600 |

SF-1.2 | 1.2 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1100×1100×1100 | 1873 |

SF-2.8 | 2.8 | 1.5-3.5 | 11 | 268 | 25 | 1.1 | 1750×1600×1150 | 2538 |

SF-4 | 4 | 2.0-4.0 | 15 | 220 | 25 | 1.5 | 1850×2050×1200 | 2838 |

SF-8 | 8 | 4.0-8.0 | 30 | 191 | 25 | 1.5 | 2200 x2900×1400 | 4129 |

SF-10 | 10 | 5.0-10 | 30 | 191 | 25 | 1.5 | 2200×2900 x1700 | 4486 |

SF-20 | 20 | 5.0-20 | 30×2 | 191 | 25 | 1.5×2 | 2850 x 3800×2000 | 9828 |

Model | Effective

volume (m³) | Capacity

(m³/min) | Rotate

speed

(r/min) | Impeller

dia.

(mm) | Motor | Single slot

weight (kg) |

Model | Power(kw) |

Rotator | Scraper | Motor

forimpeller sotor | Motor

for scraper |

XJK-0.35(3A) | 0.35 | 0.18-0.4 | 470 | 300 | Y90L-4 | Y90S-4 | 1.5 | 1.1 | 430 |

XJK-0.62(4A) | 0.62 | 0.3-0.9 | 400 | 350 | Y100L2-4 | Y90S-4 | 3 | 1.1 | 860 |

XJK-1.1(5A) | 1.1 | 0.6-1.6 | 330 | 500 | Y132M2-6 | Y90S-4 | 5.5 | 1.1 | 1380 |

XJK-2.8(6A) | 2.8 | 1.5-3.5 | 280 | 600 | Y160L-6 | Y90S-4 | 11 | 1.1 | 2330 |

XJK-5.8(7A) | 5.8 | 3-7 | 240 | 750 | Y200L2-6

(Y225M-6) | Y90L-4 | 22(30) | 1.5 | 3533 |

FAQ

Q1: How long is the warranty of the flotation beneficiation plant ?

A1: Our warranty period is one year generally.

Q2: Can I visit your factory?

A2:Yes. We warmly welcome you to visit our factory.

We will take you to our customer site to have a real look.

We will arrange a car to pick you up at the Xinzheng International Airport.

Q3: Do you provide equipment operation training?

A3: Yes. We can send professional engineers to the working site for installation, adjustment, and operation training. All of our engineers have passports.

Q4: Do you provide flow chart?

A4: Yes. Our experienced engineers are specialized in designing process flow for various project for different final product sizes.

Q5: Can you test our samples?

A5: Yes. You can send your samples to us for test and analysis.