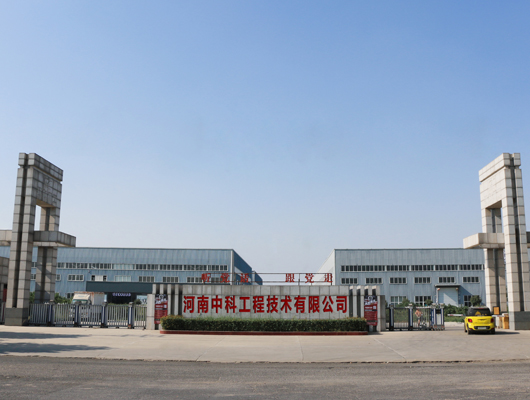

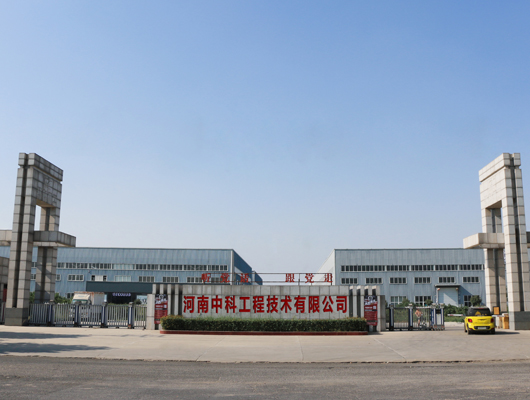

Henan Zhongke Engineering & Technology Co., Ltd. is specialized in large and medium-sized series of mining machinery, metallurgical machinery, building materials equipments, cement equipment and rotary kiln. R&D, production and marketing into a joint-stock enterprise, our company is headquartered in Zhengzhou Country’s High-tech Industrial Development Zone, which consists of three branches, a research and development department.

Since the establishment of our company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, our company develop very fast we have over 500 employees, 29 senior engineers and more than 100 middling technicians. We have a good long-term cooperation with domestic scientific research units, have introduced advanced technology and testing system at home and abroad.

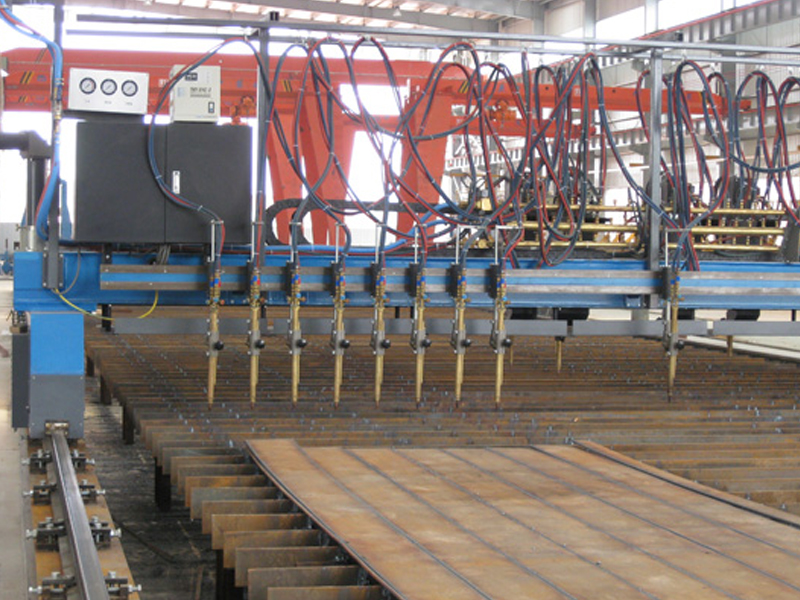

Our company pays more attention to basic managements, we constantly improve and perfect the quality management system to ensure to provide high-quality products, work site achieve fixation management, logistic achieve ABC management; our office achieve computer automatization; production technology adopt computer management; product development process design using CAD,CAPP, PROE technology. We have completed quality certification.

Our company constantly insist on the development of new products and development investment funds for technological renovation to meet with different requirements from different countries. Our products are very popular in Africa, South America and Southeast Asia.

Henan Zhongke Engineering & Technology Co., Ltd.

Factory Main Products:

Sand & stone processing series:

Vibrating feeder, jaw crusher, impact crusher, sand making machine, V-series crusher, high -efficient fine impact crusher, circular vibrating screen, sand washing machine, hammer crusher, vertical combination crusher, 2-roller crusher, transporter, stone production line, sand-making line.

Mineral processing series:

Energy saving ball mill, cement ball mill, ceramics ball mill, rod mill, floatation machine, magnetic separator, high weir spiral classifier, high gradient magnetic separator, high frequency screen, spiral chute, shaving bed, magnetic separating process, flotation separating process.

AAC block production line & cement equipment & Rotary Kiln:

Rotary kiln, cooling machine, rotary dryer, cutting machine, mould, autoclave aerated concrete(AAC) block plant equipments.

Also we can design and supply all kinds of mining production line like iron, copper, Fluorite, manganese, chromium, ilmenite, pyrite, zircon,rutile,monazite, zinc, gold, and etc. And we can supply production line, like cement production line, active lime production line, autoclave aerated concrete(AAC) block production line, ceramic sand production line.

Welcome to visit our company, we are sure we can provide you good quality products and project with best after-sale service.

Enterprise strength

With quality as the core, Henan Zhongke has established a complete set of production quality management system, and the quantitative management into the system, from product research and development, production, quality inspection, machine testing, sales to after-sales service, are rigorous, realistic, scientific dedication to create products and services to customer satisfaction

Service system

Our service commitment is not a slogan, a concept or an advertisement, our service commitment is serious. To this end, we have built a large, systematic and standardized service guarantee system, to ensure that each link is implemented in place, fine processing.

-

With business

After receiving customer requirements, we will get in touch with customers in time to understand customer specific requirements, material composition, scheduled work site and other relevant information, to help customers analyze problems and solve problems.

-

site inspection

The network, phone and other signal transmission methods give people more pictures or virtual models, which cannot make people feel personally on the scene. In view of this problem, zhongke machinery warmly welcome customers to visit our company.

-

Install back

CSTC engineers are skilled and experienced, they are conscientious and innovative, so far they have successfully completed thousands of installation and commissioning tasks of large and small engineering projects, and help customers train operators until they can operate completely independently.

Service concept

Adhere to market-oriented, innovation and development, quality and survival, to improve the after-sales service won the praise of the majority of users. Warmly welcome people from all walks of life to negotiate business guidance.

-

Pre-sale design

According to the actual needs of customers to determine the equipment model and specifications, can also be customized according to the special requirements of customers, and provide customers with production line design process, really design a satisfactory and reasonable production line for customers. All this is done at no cost to the customer.

-

Sales tracking

Follow up the production process all the time, shorten the production cycle as far as possible while ensuring product quality, and pay attention to the acceptance of products. Free of charge to send the company's senior technical personnel to assist customers to design the construction scheme, and strive to make the construction scheme reasonable and lower cost.

-

After-sales service

Free designated special after-sales service personnel, arrive at the site to guide customers to install and debug, until successful, and responsible for training operators and relevant technical personnel, until customers can fully operate production, and master certain technical knowledge and machine maintenance skills.

Henan Zhongke Engineering & Technology Co., Ltd. is specialized in large and medium-sized series of mining machinery, metallurgical machinery, building materials equipments, cement equipment and rotary kiln. R&D, production and marketing into a joint-stock enterprise, our company is headquartered in Zhengzhou Country’s High-tech Industrial Development Zone, which consists of three branches, a research and development department.

Henan Zhongke Engineering & Technology Co., Ltd. is specialized in large and medium-sized series of mining machinery, metallurgical machinery, building materials equipments, cement equipment and rotary kiln. R&D, production and marketing into a joint-stock enterprise, our company is headquartered in Zhengzhou Country’s High-tech Industrial Development Zone, which consists of three branches, a research and development department.