Introduction of magnetic separator:

Magnetic separator for particle size less than 3mm magnetite, pyrrhotite, roasted ore, ilmenite and other materials, wet magnetic separation, but also for coal, non-metallic minerals, building materials and other materials in addition to iron work. Magnetic separator magnetic system, using high-quality ferrite materials, or composites made with rare earth magnet, magnetic drum table the average intensity of 100 ~ 600mT. According to user needs, providing downstream, semi-reflux, reflux-type and so many different form strong magnetic separation. The magnetic separator is simple in structure to deal with large, easy to operate, easy maintenance and so on.

Working principle of Magnetic Separator:

When the raw materials flow into the tank body of the wet drum magnetic separator, firstly, the flowing direction of the raw materials is the same as the rotary direction of the magnetic drum, the iron magnetite materials are attracted to the surface of drum. This is the first separation. In the second step, the flushing water below flush the raw materials back for the second separation. This time the flowing direction of the raw materials is opposite to the rotary direction of the magnetic drum. Then along with the rotation of drum, the iron magnetite materials on the surface of drum will finally leave the magnetic field and fall to the ore concentrate box under gravity. Also, the flushing water above helps to flush the iron magnetite into the ore concentrate box. The weak magnetic and non-magnetic materials can not be attracted and will flow to the discharge pipe for tailings.

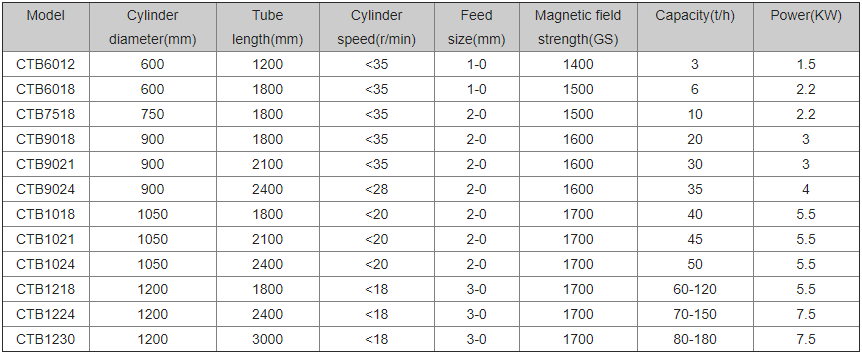

Main technical parameters of Magnetic Separator: