In the mining industry, efficient ore processing is crucial for maximizing productivity and reducing operational costs. One of the most widely used machines for grinding materials into fine powder is the grinding ball mill. But what exactly is a grinding ball mill, and how does it function? This article explores the working principles, components, and applications of grinding ball mills in the mining sector.

What Is a Grinding Ball Mill?

A grinding ball mill is a cylindrical device used to grind or blend materials such as ores, chemicals, ceramics, and paints. It consists of a rotating drum filled with grinding media (usually steel or ceramic balls) that crush and grind the material into fine powder.

Grinding ball mills are essential in mineral processing plants, where they help liberate valuable minerals from ore by reducing particle size. Their versatility makes them suitable for both wet and dry grinding operations.

Key Components of a Grinding Ball Mill

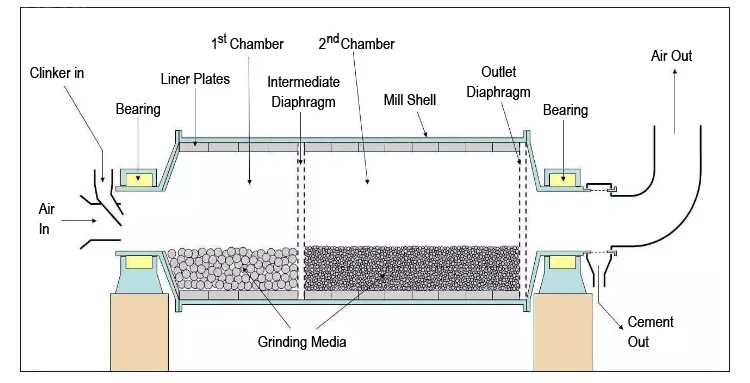

Understanding the structure of a grinding ball mill helps in optimizing its performance. The main components include:

Cylindrical Shell – The outer casing that holds the grinding media and material.

Grinding Media (Balls) – Steel or ceramic balls that impact and crush the material.

Feed and Discharge System – Allows raw material to enter and ground product to exit.

Drive System – Comprising motors, gears, and bearings to rotate the mill.

Liners – Protective layers inside the shell to reduce wear and enhance grinding efficiency.

How Does a Grinding Ball Mill Work?

The operation of a grinding ball mill follows a straightforward yet highly effective process:

1. Loading the Material

Raw material (crushed ore) is fed into the mill through a hollow trunnion at one end. The quantity and size of the feed depend on the mill’s capacity and desired fineness.

2. Rotation and Grinding Action

As the grinding ball mill rotates, the grinding media (balls) are lifted to a certain height before cascading down, creating impact and friction forces that break down the material.

Cascading Motion – Balls roll down the surface, crushing coarse particles.

Cataracting Motion – At higher speeds, balls are thrown across the mill, enhancing fine grinding.

3. Particle Size Reduction

Repeated collisions between the grinding media and ore particles result in progressive size reduction. The finer particles are discharged through a grate or screen at the opposite end.

4. Discharge of Ground Material

Processed material exits the mill, either for further processing (e.g., flotation, leaching) or as a final product.

Types of Grinding Ball Mills

Different mining operations require specific types of grinding ball mills:

Wet Grinding Ball Mill – Uses water to form a slurry, ideal for finer grinding and preventing dust.

Dry Grinding Ball Mill – Operates without water, suitable for moisture-sensitive materials.

Continuous Ball Mill – Runs non-stop for large-scale production.

Batch Ball Mill – Processes material in batches, often used in laboratories.

Applications in the Mining Industry

Grinding ball mills play a vital role in mineral processing, including:

Gold and Copper Ore Processing – Liberating precious metals from host rock.

Iron Ore Beneficiation – Preparing fine ore for pelletizing.

Cement Production – Grinding clinker into cement powder.

Phosphate and Lithium Processing – Ensuring optimal particle size for chemical extraction.

Advantages of Using a Grinding Ball Mill

High Efficiency – Capable of grinding a wide range of materials.

Scalability – Available in various sizes for small labs or large mines.

Durability – Robust construction ensures long operational life.

Adjustable Fineness – Particle size can be controlled by adjusting grinding time and media size.

A grinding ball mill is a fundamental piece of equipment in the mining industry, designed to reduce ore into fine powder for further processing. By understanding its working principles and applications, mining operators can optimize grinding efficiency and improve overall productivity. Whether used for wet or dry grinding, the grinding ball mill remains a cornerstone of modern mineral processing.

For mining companies looking to enhance their grinding operations, investing in a high-quality grinding ball mill ensures consistent performance and cost-effective material processing.