Ball mills are essential equipment in the mining industry, widely used for grinding and blending materials for mineral processing. Understanding the main components of a ball mill is crucial for optimizing its performance, ensuring efficient operation, and minimizing downtime. In this article, we will explore the key parts of a ball mill and their functions in the grinding process.

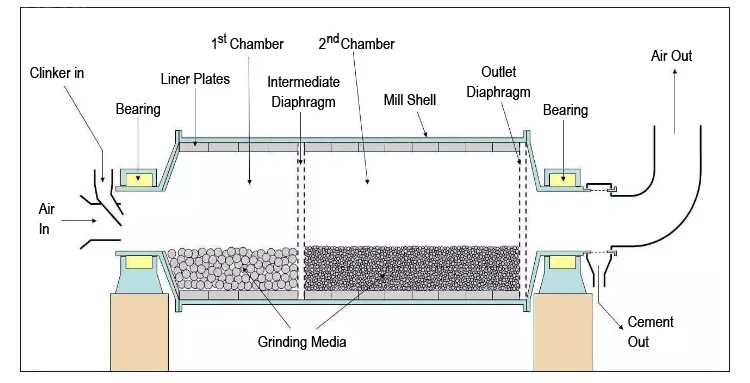

1. Cylinder (Mill Shell)

The cylinder, also known as the mill shell, is the primary structure of a ball mill. It is typically made of high-quality steel and lined with wear-resistant materials to protect it from abrasion caused by grinding media and ore. The cylinder rotates on its axis, facilitating the tumbling and grinding action necessary for material reduction.

2. Grinding Media (Balls)

The grinding media, usually steel or ceramic balls, are critical components of a ball mill. These balls impact and crush the ore as the mill rotates, breaking it down into finer particles. The size and material of the grinding balls depend on the type of ore and the desired fineness of the final product.

3. Feed and Discharge Ends

A ball mill has two primary openings:

Feed End: Where raw materials are introduced into the mill.

Discharge End: Where the ground product exits the mill.

The design of these ends ensures a smooth flow of material in and out of the ball mill, preventing blockages and maintaining continuous operation.

4. Liners (Mill Linings)

Liners protect the inner surface of the mill shell from wear and tear caused by grinding media and abrasive materials. They also enhance grinding efficiency by lifting and cascading the balls for optimal impact. Common liner materials include manganese steel, rubber, and ceramic composites.

5. Bearings

Bearings support the rotating cylinder of the ball mill, reducing friction and allowing smooth operation. High-quality bearings are essential to minimize energy consumption and prevent mechanical failures.

6. Drive System (Motor, Gears, and Pinion)

The drive system powers the ball mill and consists of:

Electric Motor: Provides the necessary torque to rotate the mill.

Gears and Pinion: Transmit power from the motor to the mill shell, ensuring consistent rotation.

Proper maintenance of the drive system is crucial for the ball mill’s efficiency and longevity.

7. Trunnion

The trunnion is a hollow cylindrical shaft at both ends of the ball mill that supports the mill shell and allows material to flow in and out. It is often lined with wear-resistant materials to withstand constant abrasion.

8. Lubrication System

A reliable lubrication system ensures smooth operation of the ball mill’s moving parts, such as bearings and gears. Proper lubrication reduces friction, prevents overheating, and extends the equipment’s lifespan.

9. Control System

Modern ball mills often include an automated control system to monitor and adjust parameters such as rotation speed, feed rate, and grinding efficiency. This enhances productivity and reduces manual intervention.

A ball mill is a complex piece of equipment with multiple critical components working together to achieve efficient grinding. Understanding these parts—such as the cylinder, grinding media, liners, drive system, and lubrication system—helps mining operators optimize performance, reduce maintenance costs, and extend the mill’s operational life.

By investing in high-quality components and regular maintenance, mining companies can maximize the efficiency and reliability of their ball mills, ensuring consistent production and profitability.

Ball mill components are essential for efficient grinding.

The ball mill cylinder houses the grinding media.

Proper lubrication enhances ball mill performance.

The drive system powers the ball mill for continuous operation.

For more insights on ball mill optimization and maintenance, stay tuned to our mining industry updates!