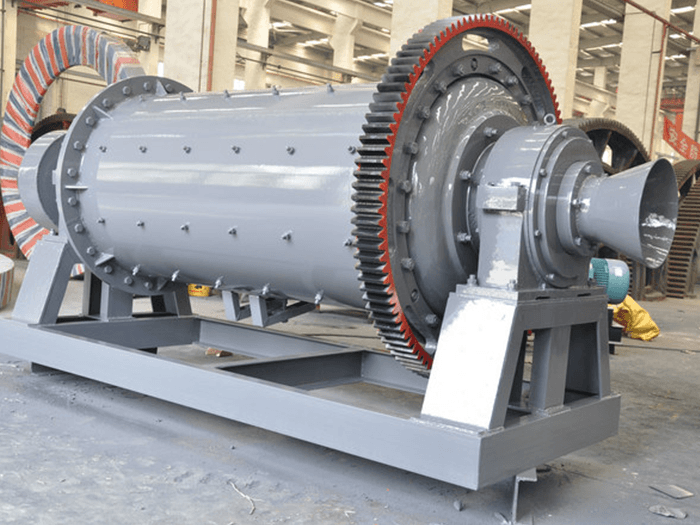

Ball mills are essential equipment in the mining and mineral processing industry, used for grinding materials into fine powders. One of the most important factors affecting their performance is the critical speed of a ball mill. Understanding this concept helps optimize grinding efficiency, reduce energy consumption, and extend equipment lifespan.

In this article, we’ll explore:

What critical speed means for a ball mill

How to calculate it

Why it matters in mining operations

Tips for optimizing ball mill performance

What Is the Critical Speed of a Ball Mill?

The critical speed of a ball mill refers to the rotational speed at which the grinding media (balls) inside the mill begin to centrifuge, sticking to the inner walls instead of cascading or falling back to impact the material. At this speed, the centrifugal force overcomes gravity, reducing grinding efficiency.

Key Factors Influencing Critical Speed

Mill Diameter – Larger mills have a lower critical speed.

Grinding Media Size & Density – Heavier or larger balls may require adjustments.

Liner Design – The mill’s internal structure affects motion dynamics.

Filling Ratio – The amount of material and grinding media inside the mill.

How to Calculate the Critical Speed of a Ball Mill

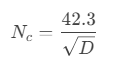

The formula to determine the critical speed (Nc) of a ball mill is:

Nc = Critical speed (in revolutions per minute, RPM)

D = Internal diameter of the mill (in meters)

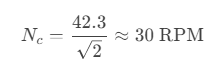

Example Calculation

For a ball mill with an internal diameter of 2 meters:

This means the mill should operate below 30 RPM to ensure optimal grinding.

Why Critical Speed Matters in Mining Operations

Running a ball mill above its critical speed leads to:

Reduced Grinding Efficiency – Balls stick to the walls instead of crushing material.

Higher Wear & Tear – Increased friction damages liners and grinding media.

Energy Waste – More power is consumed without improving output.

Optimal Operating Speed

Most industrial ball mills run at 65-75% of critical speed to balance impact and attrition forces. This ensures:

Efficient particle size reduction

Lower maintenance costs

Consistent product quality

Tips for Optimizing Ball Mill Performance

To maximize your ball mill’s efficiency:

Monitor Speed – Keep RPM below critical speed for effective grinding.

Use the Right Grinding Media – Choose ball size and material based on ore hardness.

Control Feed Size – Smaller particles grind faster and more uniformly.

Maintain Proper Filling Levels – Overloading or underloading reduces efficiency.

Regular Maintenance – Inspect liners, bearings, and drive systems to prevent failures.

Understanding the critical speed of a ball mill is crucial for mining professionals looking to enhance grinding performance and reduce operational costs. By calculating and optimizing mill speed, operators can achieve better productivity, longer equipment life, and higher-quality output.

N_c = \frac{42.3}{\sqrt{D}}

N_c = \frac{42.3}{\sqrt{D}}