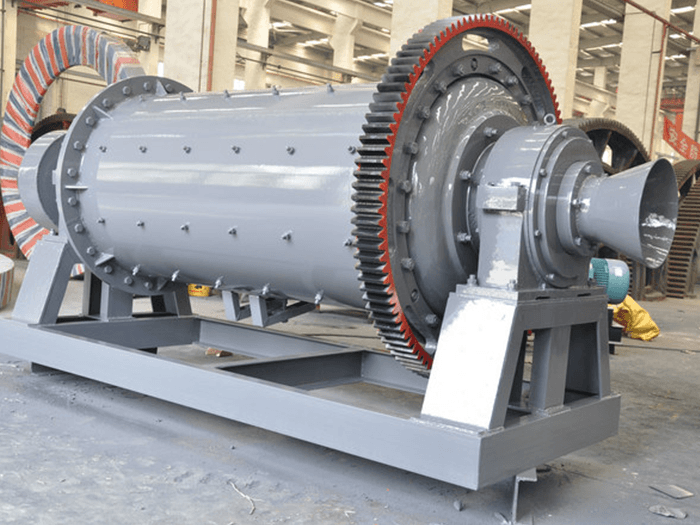

Ball mills are widely used in industries like cement, mining, ceramics, and chemicals for grinding materials into fine powders. But what makes them so effective? In this article, we explore the key advantages of using a ball mill for grinding, helping you understand why it remains a preferred choice for many applications.

1. High Grinding Efficiency & Uniform Particle Size

Ball mills use impact and attrition forces to break down materials, ensuring a consistent and fine grind. The rotating drum filled with grinding media (steel or ceramic balls) crushes materials into uniform particles, which is crucial for industries like cement production and mineral processing.

✅ Key Benefit: Produces a homogeneous product with controlled fineness, improving downstream processes.

2. Versatility in Material Processing

Unlike some grinding machines limited to specific materials, ball mills can handle:

Hard materials (ores, minerals)

Brittle materials (limestone, clinker)

Wet or dry grinding (slurries or powders)

This flexibility makes them ideal for cement plants, mining operations, and chemical industries.

3. Low Energy Consumption (Compared to Alternatives)

Modern ball mills are designed for energy efficiency, reducing operational costs. Features like:

Variable-speed drives

Optimized grinding media loading

Advanced liner designs

…help minimize power usage while maintaining high output.

📊 Fact: Energy-efficient ball mills can cut electricity costs by 15-30% compared to traditional grinding mills.

4. Durability & Low Maintenance

Ball mills are built with robust materials (high-grade steel, wear-resistant liners), ensuring long service life even in harsh conditions. Maintenance is straightforward, with easy access to internal components for inspection and replacement.

🔧 Pro Tip: Regular lubrication and monitoring of grinding media wear can further extend lifespan.

5. Scalability for Industrial Production

Whether you need a small lab-scale mill or a large industrial mill, ball mills can be customized for different capacities. This scalability makes them suitable for:

Pilot testing (R&D)

Full-scale production (tons per hour)

6. Precise Control Over Grinding Parameters

Advanced ball mills allow adjustments in:

Rotation speed

Grinding media size & density

Residence time

This ensures optimal grinding conditions for different materials, improving efficiency and product quality.

7. Cost-Effective Over the Long Term

While the initial investment may be higher than some alternatives, ball mills offer:

Lower operational costs (energy & maintenance)

Higher throughput

Longer lifespan

…making them a cost-effective solution for continuous grinding operations.

Is a Ball Mill Right for Your Needs?

Ball mills provide high efficiency, versatility, durability, and cost savings, making them a top choice for grinding applications in cement, mining, and more.

🔗 Want to optimize your grinding process? Contact our experts to find the best ball mill solution for your needs!