Introduction

Ball mills are essential equipment in cement, mining, and mineral processing industries, used for grinding materials into fine powders. One of the most critical factors in ball mill operation is determining the required power, as it directly impacts energy consumption, operational costs, and grinding efficiency.

In this guide, we’ll explain the key factors influencing power demand and provide step-by-step calculations to help you estimate the necessary power for your ball mill accurately.

Key Factors Affecting Ball Mill Power Requirements

Before calculating power, it’s important to understand the variables that influence energy consumption:

Mill Dimensions (Diameter & Length) – Larger mills require more power.

Rotational Speed – Expressed as a percentage of critical speed (typically 65%-75%).

Filling Ratio of Grinding Media – Optimal filling is usually 30%-40% of mill volume.

Material Properties – Hardness, density, and feed size affect grinding resistance.

Liner Type & Mill Design – Smooth liners reduce friction, while ribbed liners enhance lifting.

How to Calculate Ball Mill Power

The most widely used method for power calculation is Bond’s Law and the empirical formula derived from industrial mill data.

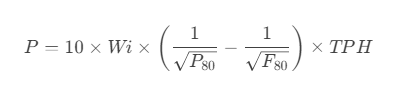

1. Bond’s Work Index Method

The Bond Ball Mill Work Index (Wi) is a measure of material grindability (kWh/ton). The formula for net power consumption is:

Where:

= Power (kW)

= Bond Work Index (kWh/ton)

= 80% passing size of product (µm)

= 80% passing size of feed (µm)

= Throughput (tons per hour)

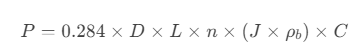

2. Empirical Formula for Ball Mill Power

A simplified industrial formula for approximate power calculation is:

Where:

= Mill diameter (meters)

= Mill length (meters)

= Mill speed (rpm)

= Filling ratio of grinding media (decimal, e.g., 0.3 for 30%)

= Bulk density of grinding media (tons/m³, typically 4.5 for steel balls)

= A correction factor (depends on mill type & liner design, usually 0.6–0.8)

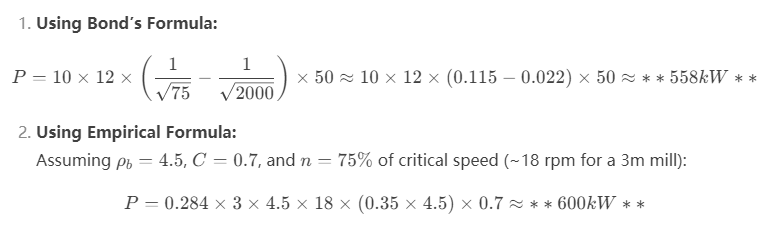

Practical Example Calculation

Problem:

Calculate the power for a 3m x 4.5m ball mill running at 75% critical speed, with a 35% media filling ratio, processing 50 TPH of cement clinker (Bond Wi = 12 kWh/ton), feed size F80 = 2000 µm, and product size P80 = 75 µm.

Solution:

The slight difference is due to approximations, but both methods provide a reliable estimate.

Tips to Optimize Ball Mill Power Consumption

Use high-efficiency motors & VFDs to adjust speed based on load.

Optimize grinding media size & filling ratio to reduce energy waste.

Regular maintenance of liners and bearings minimizes friction losses.

Pre-crushing feed material reduces grinding workload.

Calculating the required power for a ball mill ensures energy-efficient operation and cost savings. By applying Bond’s Work Index or empirical formulas, you can estimate power needs accurately. For customized solutions, consult with ball mill manufacturers to fine-tune performance.

📌 Need help with your ball mill setup? Contact our experts today for a free consultation!