5 stage preheater main market: middle east Asia Africa Ameri , We supply best quality 5 stage preheater.

This equipment is a kind of heat exchange equipment in the system of dry process rotary kiln. Under conditions of suspension,

the dry raw meal would exchange heat and separate with the hot air flow coming from the kiln.

The equipment possesses any advantages such as: good preheat effect. Suitable for any cement raw materials,

not easy to be damaged and blocked up. Materials fed into the kiln easily to be separated, and the system is well sealed .

Main Structure of Preheater:

Vertical preheater system primarily include six parts.

1. The upper feeding system: mainly include the upper hopper and feeding pipes. The way of the feeding and its structure can guarantee the safe sealed status during the feeding process.

2. Preheated body: it is composed of preheating room, hang unit and fire-resistant brick liner. The preheated body is the most important part which ensure the material can be preheated to 900 centigrade.

3. Push device: mainly include push head, framework and connection rods, etc.

4. Hydraulic system: mainly include the fuel tank, fuel pump, motor, electonic magnetic valva and fuel pipe, etc.

5. Lower part feeding room: include slide pipe, feeding room body and feeding slide glib, etc.

6. Framework: it mainly includes the vertical column, beam and other parts.

Working Principle of preheater:

When the raw materials feeding into the preheater, under the negative pressure condition, to prevent cold air into the preheater, the inlet of raw materials must take effective seal. This is to ensure the effective use of heat and material preheating effect. The standard of preheating quality in the preheater, is the feeding room’s temperature which is in the bottom of preheater. Kiln temperature is: detected by thermocouple in the side wall of feeding room, including the flame radiation and air temperature. It reflects the firing temperature when feed into kiln, but also the degree of feedback the final warm-up temperature of the material. To Preheater, Truly reflects the effective temperature of the material is outlet temperature of the preheater top. Temperature control on this point is more important than the end of the rotary kiln temperature control. Within preheater, materials after preheating and pre-decomposition, pushing out from Preheater to Rotary kiln by hydraulic plunger device.

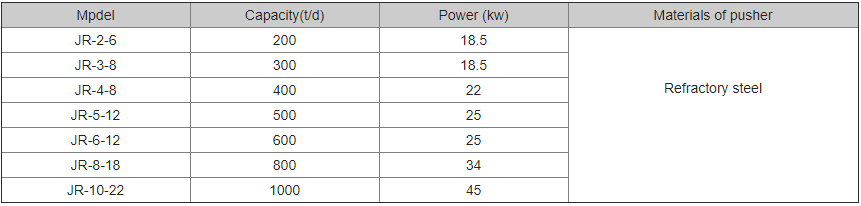

Main technical parameter: