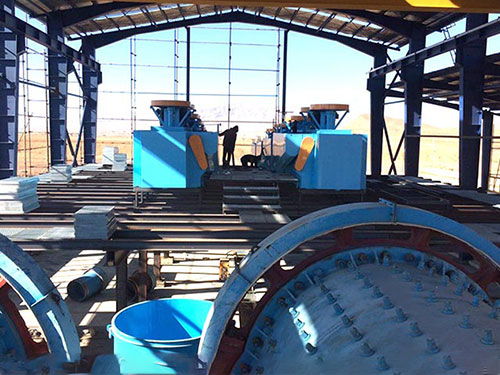

Why Choose Our Ore Processing Ball Mills?

1. Precision Engineered for Maximum Ore Recovery

Our ball mills are designed to grind and liberate minerals efficiently, ensuring higher concentrate grades and reduced waste in gold, copper, and lithium processing.

2. Energy-Saving Technology

3. Reliable & Low-Maintenance Design

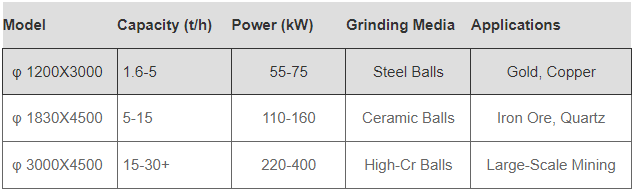

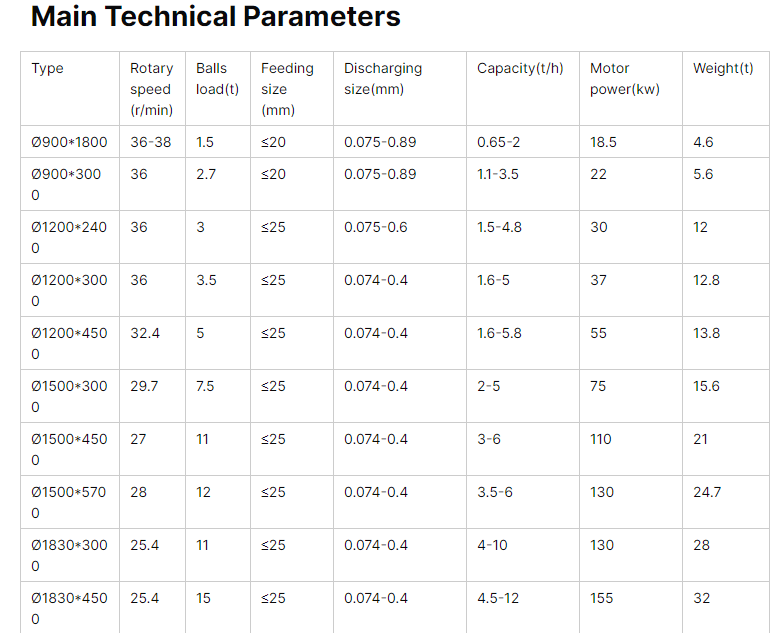

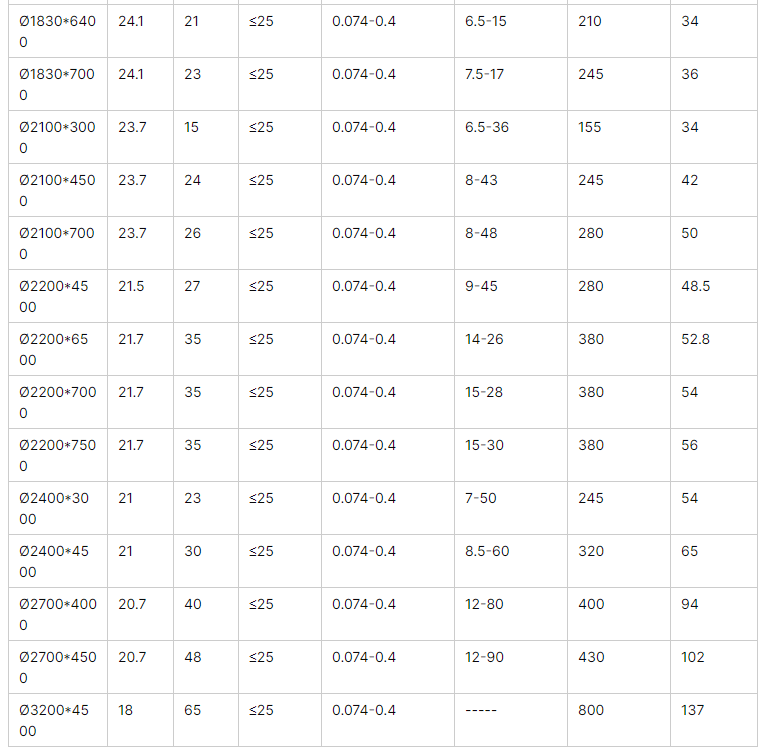

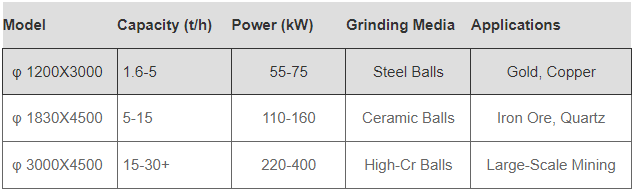

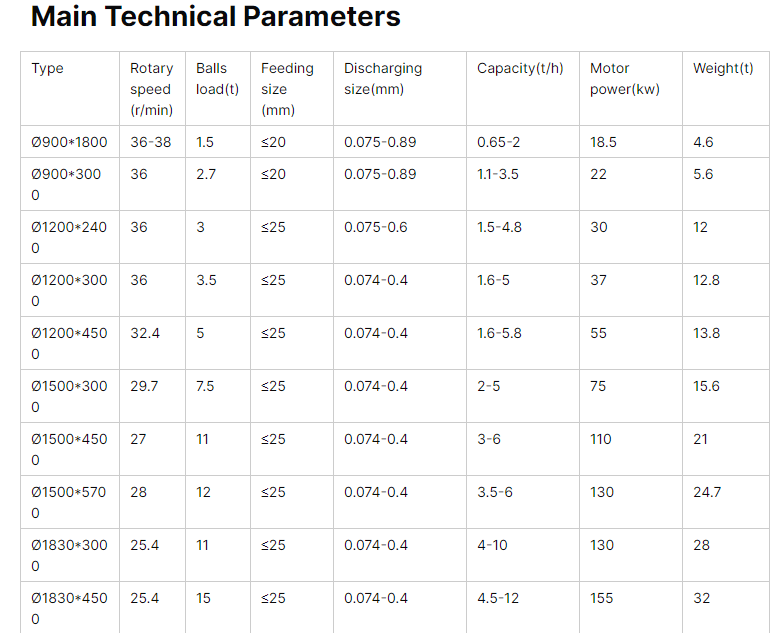

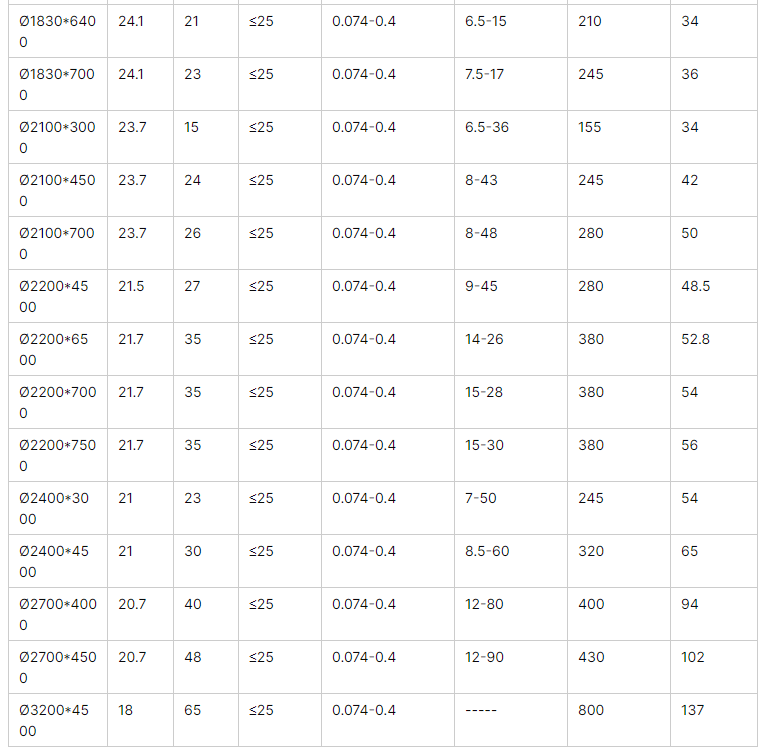

Technical Specifications

(Custom configurations available for large-scale mining operations.)

Applications in Ore Processing

✅ Gold Ore Grinding – Optimal particle size for cyanide leaching.

✅ Copper Concentrate Production – High throughput with low wear.

✅ Lithium & Rare Earth Minerals – Ultra-fine grinding solutions.

Trusted by Global Mining Companies

Case Study:

Client: Copper Mine in Chile

Solution: Installed 2x BM-2000 Ball Mills for 40 TPH throughput.

Result: 15% energy savings and 10% higher recovery rates vs. previous system.

View More Case Studies

Frequently Asked Questions (FAQs)

Q1: How long is the warranty of the ball mill?

A1: Our warranty period is one year generally.

Q2: How long shall we replace the grinding ball?

A2: Usually 6-12 months(Depends on the hardness of your raw material)

Q3: Do you provide beneficiation flow chart?

A3: Yes. Our experienced engineers are specialized in designing process flow for various ores beneficiation, including iron ore, tin ore, copper ore, gold ore, lead zinc ore, manganese ore, etc.

Q4: What’s the price range?

A4: Ball mills start at $50,000 (varies by size and customization). Contact us for an exact quote.