Ceramic ball mill is mainly used for materials mixing and grinding.The products size is uniform,and can save power.Ceramic ball mill not only can wet grind ,but also can dry grind.The ceramic ball mill can adopt different types of lining board according to the production requirement. The grinding fineness of the grinding operation is relying on the grinding time to control.

Ceramic ball mill has the features of less investment, saving energy and electricity compared with the similar products

| Name: | Ceramic ball mill | Loading Weight (ton/time): | 0.05-15 |

|---|---|---|---|

| Reference Power(KW): | 2.2-75 | Control System: | PLC Computer |

| Rotate Speed (r/min): | 13.5-50 | Liner Material: | Ceramics, Silica, Rubber, Metal |

| High Light: | Intermittence Ball Mill Grinder,15kw Ball Mill Grinder,15kw Intermittence Ball Mill | ||

Main Technical Parameters of Ceramic Ball Mill:

| Model | Loading Weight (ton/time) | Rotate Speed (r/min) | Reference Power(KW) | Liner Material |

| 600×700 | 0.05 | 50 | 2.2 | Ceramics, Silica, Rubber, Metal(Equipped power will be a little different according to the liner material and the processed material) |

| 800×600 | 0.075 | 42 | 3 | |

| 900×1200 | 0.2 | 38.5 | 5.5 | |

| 1300×1500 | 0.5 | 33 | 7.5 | |

| 1500×1800 | 1.2 | 28.5 | 11 | |

| 1800×2000 | 1.5 | 24 | 15 | |

| 2600×2800 | 5 | 16.5 | 37 | |

| 3000×3800 | 10 | 14.5 | 57.2 | |

| 3200×4600 | 15 | 13.5 | 75 |

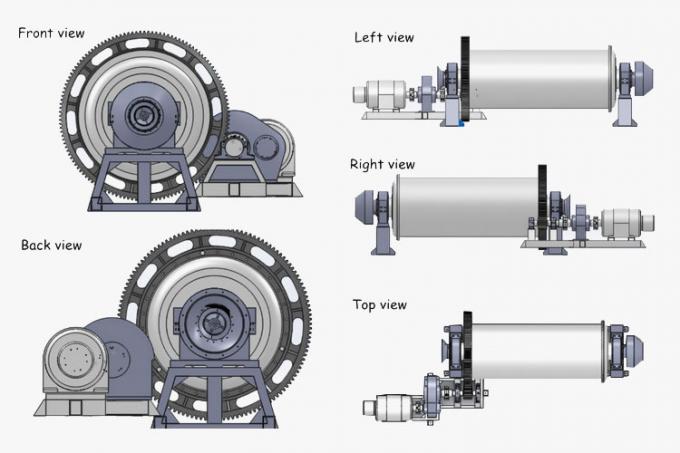

Working Principle:

Our ceramic ball mill is of horizontal, cylindrical and tubular structure. It comes with two cabins and is a grate ball mill. The materials are evenly fed through the charging device to first warehouse where there are step scales boards, corrugated scale boards and different specifications of steel balls. When the cylinder rotates, the centrifugal force produced causes the steel balls to impact and grind the materials in the ball mill. The materials are then lead to the second cabin for further milling until they turn into powders and are discharged from the outlet.

Application:

As a piece of mineral processing equipment, a ball mill is widely used in beneficiation, building material and chemical industries. Ball mill is suitable for dry-type ore grinding and wet-type ore grinding. According to different discharging methods, ball mills fall into grate ball mill and overflow ball mill.

Ceramic Ball mill is a mineral processing machine for milling the materials into powders after they are crushed. It is widely applied to the production of cements, silicate products, building materials, fireproof materials, fertilizers, glass, ceramics as well as nonferrous and ferrous metal processing industries. It could carry out dry and wet millings on different materials.