Motor power: 55-950×2kw

Capacity: 180-10000t/d

Kaolin feed particle size: 125-1500mm

Slag powder/ceramsite sand finished particle size: 0.074-0.4mm

Motor power: 55-950×2kw

Capacity: 180-10000t/d

Kaolin feed particle size: 125-1500mm

Slag powder/ceramsite sand finished particle size: 0.074-0.4mm

What is cement rotary kiln?

Cement rotating kiln is a type of rotary kiln in the rotary kiln. It is a kind of rotary kiln specially treated with cement. Therefore, it is named. The currently produced cement rotating kiln is mainly a kind of equipment for the drying method of cement clinker and wet production line.

Material: Cement/Limestone /Bauxite /Zinc Oxide /Ceramsite /Sludge

How does cement rotary kiln work?

1. Broken and pre -equalization: Most raw materials need to be crushed and can be put into use, such as limestone, clay, iron ore and coal.

2. Requirement of raw materials: Add the processed raw materials to the rotary kiln from the feed inlet.

3. Preheat and decompose: At the front of the rotary kiln, preheat raw materials to achieve the temperature required for the restoration of the reaction.

4. Burning of cement clinkers: The carbonate in the rotating kiln further decomposes further and a series of solid -phase reactions occur to generate cement clinkers.

5. Cooling: At the back of the switching kiln, the cement clinker cooler cools the high temperature clinker unloaded from the swing of the kiln to a reasonable temperature.

6. Cement powder grinding: Cemental powder is the last process of cement manufacturing, and it is also a process that consumes more power. Its main function is that the cement ball mill is ground to grind the cement clinse (and glue condens, performance adjustment materials, etc.) to the appropriate particle size (represented by fineness, comparison surface area, etc.).

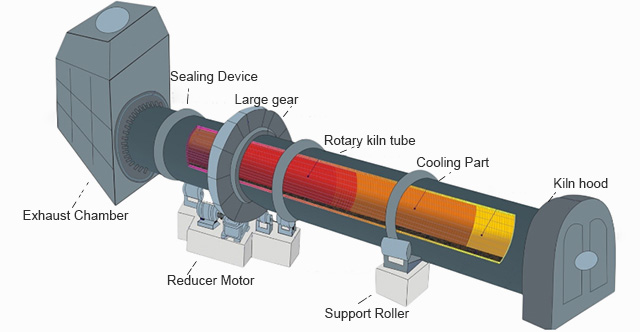

Cement Rotary Kiln Diagram:

Your Benefits:

Mature technology and high production efficiency: Cement rotation kiln is one of the current mature production equipment in cement production.

Can adapt to a variety of cement production processes.

Can adapt to a variety of cement materials: including limestone, clay, iron ore, plaster, etc., which are more flexible in production.

Low production energy consumption: Cement return kiln can achieve material rotation at high temperature and reduce energy consumption.

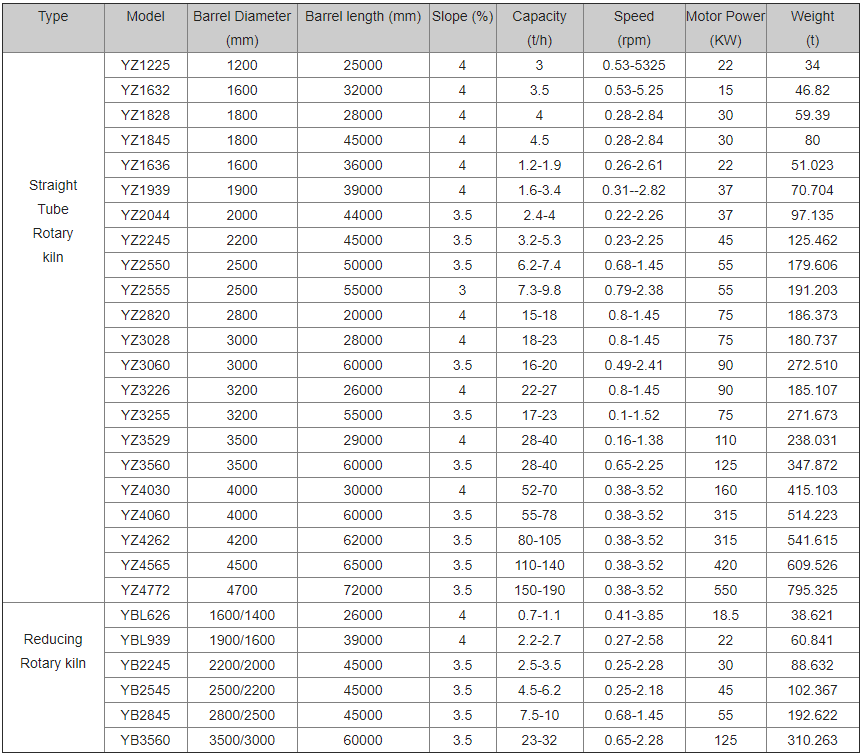

CEMENT Rotary Kiln Specifications: