Working principle of Cement Grinding plant

The production of cement, generally can be divided into raw meal preparation, clinker calcining and finished cement three processes, etc. Silicate cement production technology is representative in the cement production, is a limestone and clay as the main raw material, through crushing, ingredients, which takes limestone and clay as the main raw materials, through crushing, burdening, grinding to fine particles to get the raw meal, then feeds into the cement kiln to calcination to get the cement clinker, mix some gypsum into the clinker(sometime with mixed materials and admixture) to grind int portland cement.

Cement Clinker Grinding Station Requires Following Raw Materials :Clinker, Gypsum and Blending Materials.

Cement Clinker Grinding Plant includes:a. Gypsum and Blending Materials Crushing Systemb . Cement Proportioning and Grinding Systemc. Cement Storage and Bulk Loadingd. Cement Packing and the finished-product Storage.

Main equipment of Cement Grinding Plant

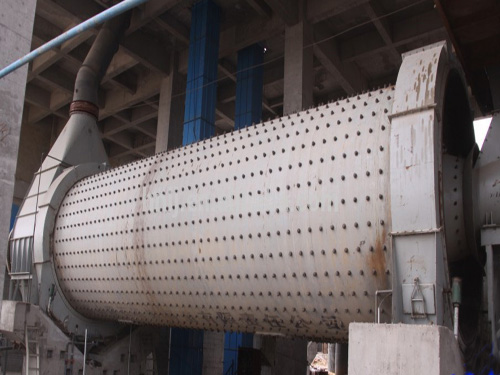

Grinding Mill : Cement Ball mill , Vertical Mill

Feeding Machines : Apron Feeder , Impeller Feeding machine , Magnetic Vibrating Feeding Machine ect.

Conveying Equipments : Bucket Elevator, Belt Conveyor, Chain Conveyor , ect.

Crushers : Jaw Crusher, Hammer Crusher, Impact Crusher ect .

Dust Collectors / Dust Filters : Bag type Dust Collector / dusct filter, Pulse bag Dust Collector, Air box type pulse bag dusct collector ect .

High effecient powder separator : High Efficient Horizontal whirling-fluid Powder Separator, Centrifugal powder separator/ concentrator , cyclone powder concentrator ect.

Packing Machines : Automatic Cement Packing Machine , 1-12 spouts cement bag rotary packing machine ect .

Features of Cement Grinding Plant

Uses pre-crushing technology, so that it reduces the granularity of the materials that are fed into the grinding mill .

Promotes the materials to produce flaws and defects inside.

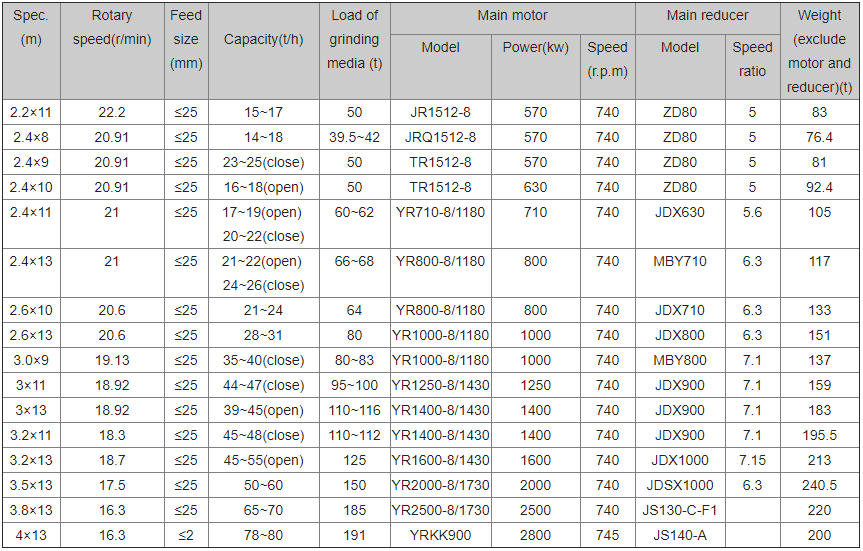

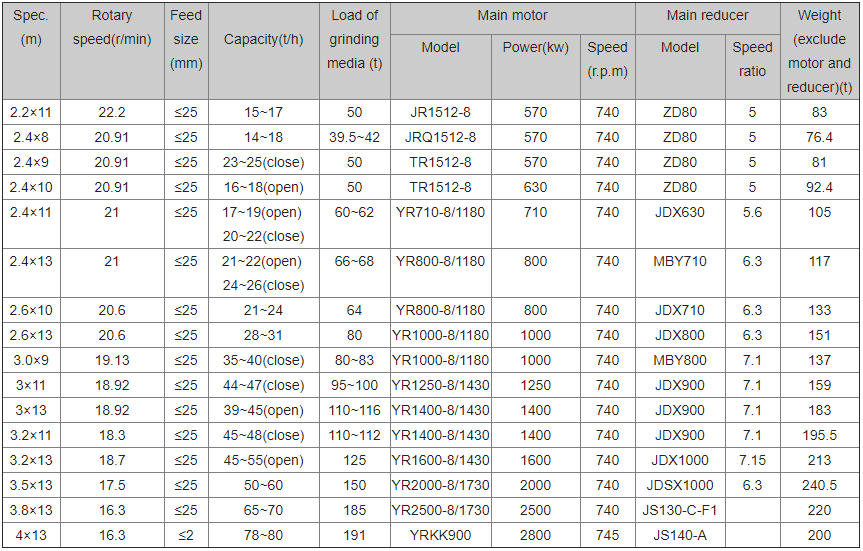

Technical parameters of cement grinding