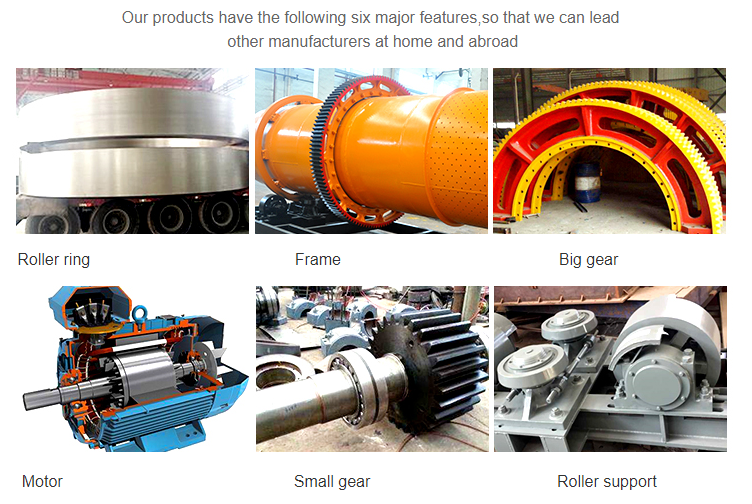

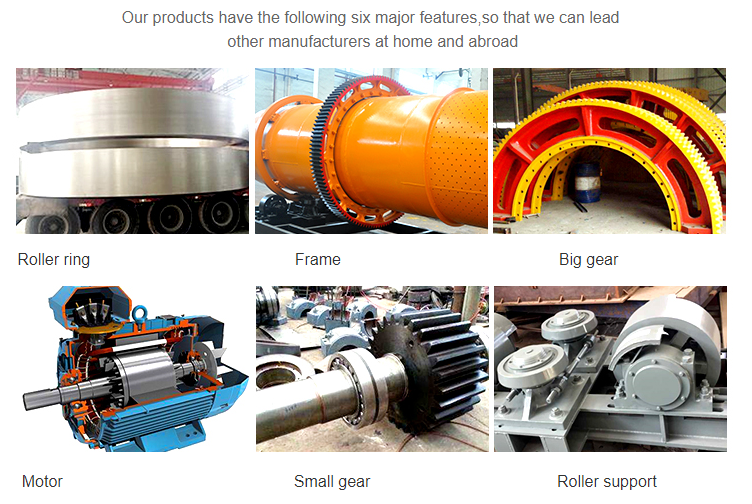

Supporting equipment of sawdust dryer:

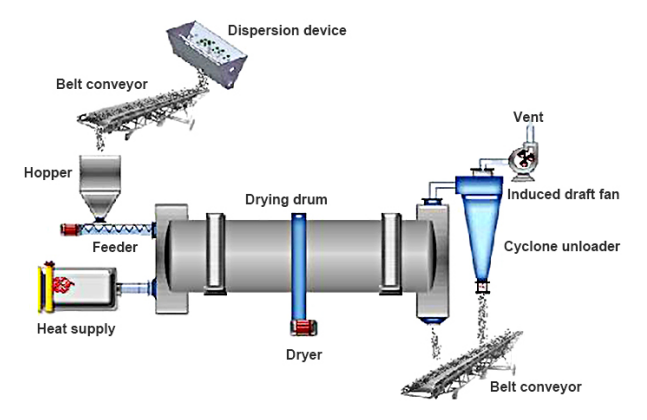

Sawn drying equipment structure: It is mainly composed of heat sources, dispersing device, band feeder, feeder, rotary roller, transmission component, band -mounted material, citaker, unloader and power distribution cabinet.

Product details:

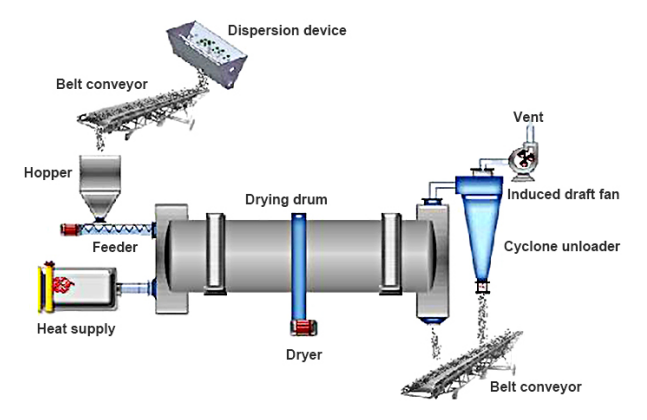

Schematic Diagram:

Principle of sawdust dryer:

The principle is as follows: Powder -like or granular flour ash is transported from the band feeder to the feeder, and then the material is transported to the dried drum from the feeder. Below, fully scattered with the hot air to fully contact the hot air to achieve the purpose of heat transfer and quality. The drying material is discharged from the roller terminal through the star -shaped unloader, and the dry product outputs the dry product and complete the drying process.

The effect of rotary wood dryer:

The sawdust dryer is a granular wet saw, and the spiral conveyor is continuously added to the dry pipe. In the conveying and decentralization of high -speed thermoscopic, the moisture in the wet material evaporates the pink or granular dry products.