Description of Rotary Dryer

The Rotary dryer made by our company is mainly used in building materials, metallurgy, chemical plant, cement plant for drying of limestone slag, coal powder, slag, clay stone. This dryer is formed by rotary body, lifting blade, driving device, supporting device and sealing ring. The dryer has advantages of reasonable structure, high efficiency, low energy consumption and convenient for transportation.

Working principle of Rotary Dryer:

Materials are sent to hopper of rotary dryer by belt conveyor or bucket elevator.The barrel is installed with slope to horizontal line. Materials enter the barrel from the higher side, and hot air enters the barrel from the lower side, materials and hot air mix together. Materials go to the lower side by gravity when the barrel rotates. Lifters on the inner side of barrel lift materials up and down to make materials and hot air mix completely. So drying efficiency is improved.

Features of Rotary Drier:

Compared with other dryers, rotary drying machine has the following features:

1. Large production capability, continuous operation.

2. Simple structure, convenient operation.

3. Low malfunction, low maintenance cost.

4. Wide scope of application. It can be used for drying granular materials, especially benefit for those materials with big adhesion.

5. Great operating flexibility. The production allows a larger fluctuation range in the output of products, but not influence the quality of product.

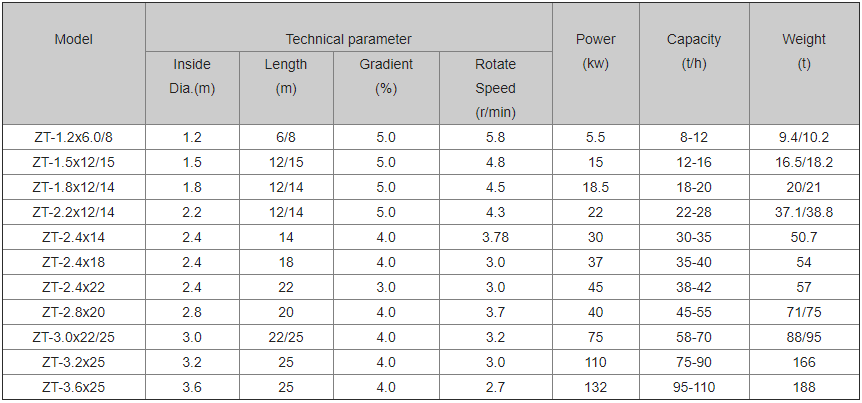

Main technical parameter: