The advantage of Lime production line :

The following measures should be taken in order to improve lime production and activity:

In terms of environmental protection: The temperature of the flue gas discharged by the vertical heater of the kiln tail and the low dust content, which makes the configuration of subsequent flue gas treatment simple and meet environmental protection requirements.

In terms of lime activity: The rotary kiln is open -type burning, the kiln body is simple, the airflow is smooth, and the sulfur -containing gas can be discharged in time. The sulfur in the fuel is not easy to attach, so the product is low in sulfur content and meets the steelmaking requirements.

In terms of energy saving: Configuration vertical heater at the tail of the kiln can make full use of the high -temperature flue gas generated in the rotary kiln, which can not only greatly increase the output of the rotary kiln, but also fully reduce the thermal consumption of unit products.

The process of Active Lime production line :

(1) Material storage transportation delivery

Lime stone with a particle size of 10 to 50mm is transported to the factory area and stacked in the field. The material of the granularity is qualified from the loader to the feed tank set by the stone material, and the material is quantified by the feeder under the feed tank. After the segmentation of the section of the section of the passage, the large dumping conveyor will be sent to the tip of the preheat at the top of the heater. The sieve is sent from the conveyor to the yard to regularly ship out from the forklift.

(2) Limestone burn

Limestone burning is composed of vertical heater+rotary kiln+vertical cooler. The output is 150 ~ 1200T/d. The high -temperature flue gas passed in to preheat the material to above 1,000 ° C, so that the limestone will be partially decomposed, and then the hydraulic push rod is pushed into the rear of the rotary kiln in turn. Cold the cold air cooling, cool down the material to the ambient temperature+60 ° C and discharge the cooler. The air blowing through the cooler is used as a secondary air to enter the rotary kiln to participate in the combustion.

(3) Products transportation

The finished lime is transported to each finished limestone library by the chain board conveyor, bucket promotioner, and band conveyor. The lime storage warehouse is used to remove the lime in the warehouse into the car and tanker. Set up different sizes according to the customer reserves requirements.

The finished storage warehouse adopts a circular storage warehouse, with 2 finished warehouses of 5 ~ 50mm, and<5mm finished warehouse, and the amount of each storage warehouse is about 800T;

(4) Fonter gas treatment

The high -temperature smoke generated by the burning kiln burning. After the heat exchange with the limestone in the preheating device, the temperature drops to less than 250 ° C, and then the cyclone dust collector is carried out for a first -class dust collection, the large particles of dust are captured, and then the large particles of dust are captured. Enter the bag dust collector, discharge the atmosphere through the high temperature fan after the dust removal, and the dust concentration of the emission gas is less than 30mg/m³. Set up a cold air control system in the dust collector import to protect the dust collector.

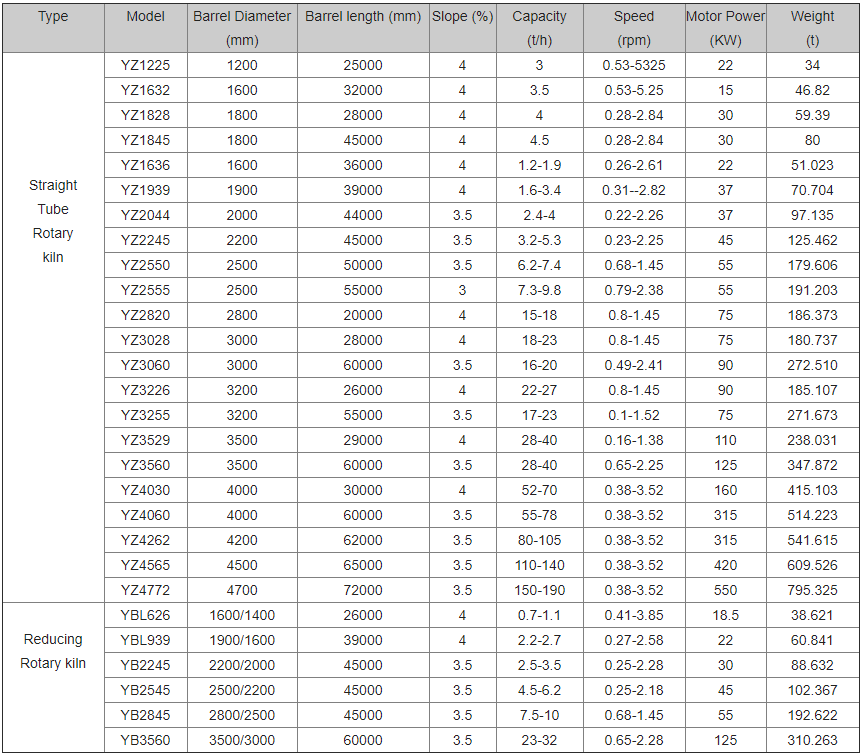

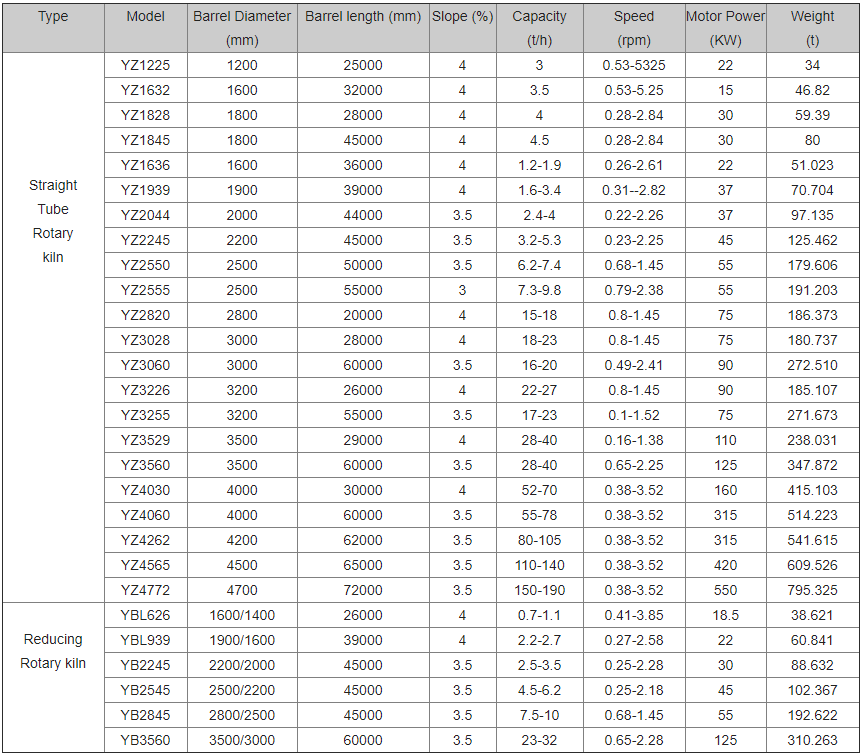

Main technical parameters of lime kiln: