Description of Lime Kiln

Lime kiln is the main equipment for sintering cement clinker. The rotary kilns produced by our company can be divided into dry process and wet process. They can also be used for chemical industry, metallurgy industry and etc. Through technical renovations, the rotary kiln sintering system equipment made by our company has adopted high measuring precession plunger pump, variable speed adjusted valve, contact graphite block air seal and other national advanced technologies. In order to raise up automation degree, indurstrial TV has been used at the kiln head for monitoring of kiln, analog fluorescent screen has been used for display of process flow; infrared scanning system has been adopted for sintering zone to directly reflect the burning conditions on the computer. With the use of these new technologies, it is directly in vision , convenient in operation and reliable in use.

The structure characteristic of lime rotary kiln:

1. The lime rotary kiln shell design fully take into consideration of the corner at shell flexible supporting to extend the lifetime of refractory bricks and castings.

2. Adopt supporting roller bearing with big diameter and small ratio between length and diameter to improve the reliability. The bearing is automatic self-sligning bearing.

3. The better sealing effect of new type open gear hood sealing type.

4. The spring lamination overlying type lexible sealing, double layer spring lamination sealing increase the heat insulation layer to improve the reliability and lifetime.

Features of lime rotary kiln:

1.Support device: advanced shaft structure, automatic temperature measuring device and electrical heating.

2.Catch wheel : including two kinds mechanical wheel and hydraulic pressure.

3.Gears:single or double. Control the rotating speed by buncher, DE machine and frequency variable motor. Be reliable , energy-saving, and efficient.

4.Cylinder tyre bolster: lower bolster has three types: fixed , zoom and floating. The structure is simple ,replacement is convenient and won’t hurt cylinder.

5.Kiln head hood: including stationary type and flexible type.

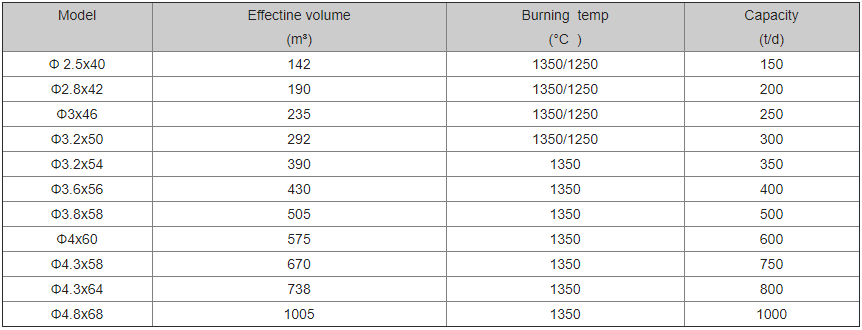

Main technical parameter: