Aerated concrete block body in autoclaved kettle after steam products get high strength.In aerated concrete block production generally choose design pressure 1.5 MPa, work pressure 1.4 MPa, both ends on the door, on both sides of the air intake form of autoclaved kettle.

Aerated concrete block production at the environment of high temperature and saturated steam, so the aerated concrete block production line according to the general requirements when the boiler equipment production allocation rated working pressure of 1.6 Mpa, the steam boiler temperature above 200 ℃.

Structure of Autoclave Boiler:

The main pressure parts material: simplified kettle lid is made of 16 MNR steel plate, steel plate GB6654 standard rules. Kettle, kettle cover flange at the flange use 16 mn overall forging processing, forging JB4726 2000 standard | | level regulation, and one by one for ultrasonic nondestructive testing, the indicators meet the corresponding provisions of the JB/T4730.3-2005. Open the door way: through type or end type.Through type refers to both ends with kettle cover, end type refers to install kettle cover at one end.Kettle lid open means: tooth quick-opening structure, driving mode split, electric, pneumatic and hydraulic transmission.With a kettle door open close the safety interlock.

Features of Autoclave Boiler:

1.To choose angang 16 MNR container plate, chamfering break mouth, using autoclaved kettle oil a built in welding process, and pressure parts shoot X-ray flaw detection, to ensure that the welding process.

2.Kettle, kettle door use 16 mn secondary forging parts, annealing, heat treatment, kettle door before delivery has heat preservation.

3.Reducer adopts gear lever, different from other manufacturers of cycloidal pinwheel reducer, a triple protection (1) electronic interlocking device (2) manual interlock (manual screw) (3) hand speed reducer.

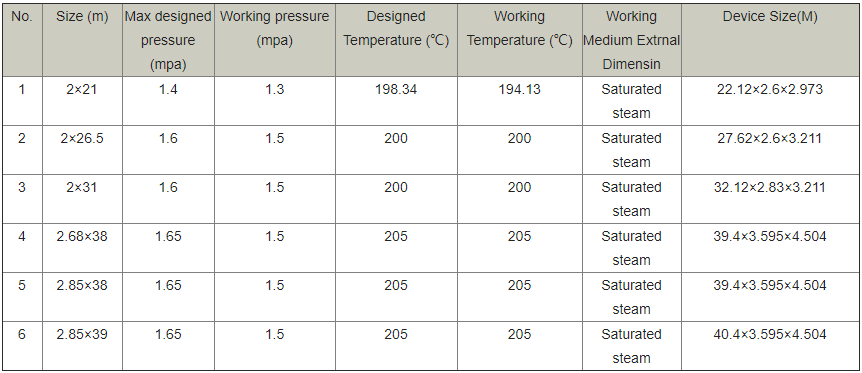

Main technical parameter: