Cutting machine is the main equipment for Autoclave Aerated Concrete(AAC) products, it's necessary core equipments for capacity more than 50000 m ³/year, it's also necessary to increase the AAC capacity.

Our cutting machine adopts advanced technology, with only one step,cut the cake in six sides, no need of hang the cake for second time,reduces the damage to the cake. So our cutting machines are welcomed all over the country,and gain honor from all our users. After years technology innovation,nowdays,we are able to produce many models of AAC cutting machies.

2) Working principle of cutting machine

After the poured blocks are turned over for ninety degrees in the air, hoisted to the cutting car and stripped off the mould frame, then the cutting car carried it to the longitudinal cutter and the traverse cutter position, and the longitudinal cutter and the traverse cutter will cut them on six sides. First of all, the longitudinal cutter cut the block longitudinally and horizontally on four sides. When this operation is completed, the cutting car will carry the block stay under the traverse cutter position, so that the block is cut vertically on the remaining two sides by the traverse cutter. After cutting is finished, the block will also carried by the cutting car to the position under semi-finished hoisting tool , then the semi-finished hoisting tool will hoisted the block to the steaming and curing wheelbarrow. Then the car will go back quickly ,carry the block for the next cutting mould. Cutting cycle is less than seven minutes.

3) Advantages of the ground overturn cutting machine

1. structure Compact, easy to operate, less maintenance.

2. the level cutting and vertical cutting can be finish only once.

3. cut the cake in 6 sides,the final product accuracy is accord with standard of GB.

4.Can also satisfy the requirement of producing slab, the final product accuracy is accord with standard of GB.

5. Can recycle all the waste slurry, no secondary pollutation.

6. Cake no conglutination.

7. Level cutting adopt screw drive, solve the original problem of the lack of synchronization by hydraulic transmission.

8. No Limit and interlocked in mechanical systems to prevent accident by the improper operation of the equipment.

9. Have rapid replacement wire device.

10. No collapsing.

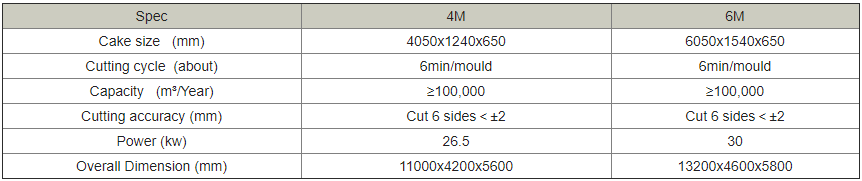

Main technical parameter: