Gold ore grinding processing -Gold Mine milling machine

The granularity of the dismissal 0.074-0.89mm

Processing ability: 0.65-615t/h

Scope of application: grinding and processing of gold ore, and deep -scoring grinding of other related ore.

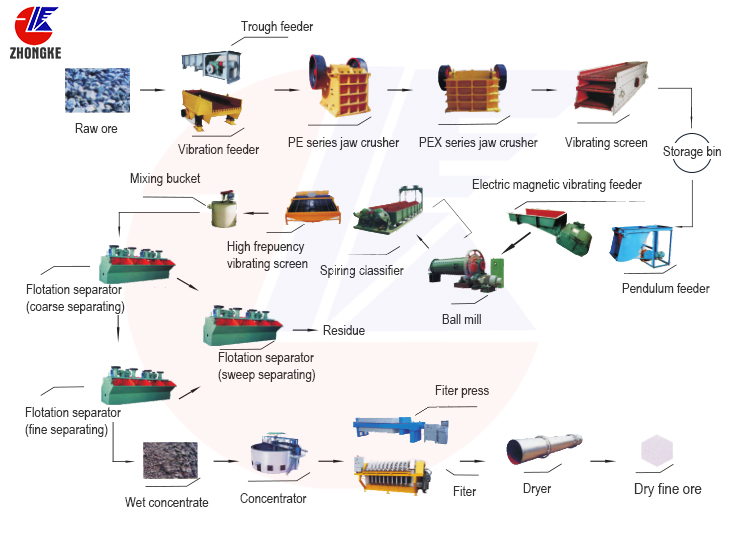

Because most of the gold mines contain impurities, a series of mineral selection processes need to be obtained by a series of mineral procosses such as crushing, grinding, and screening. Special abrasive equipment -gold ore grinding machine, which effectively improves the recovery and utilization rate of gold ore, has attracted widespread attention from users.

The main structure of the gold ore grinding machine includes feeding devices, support devices, rotation parts, unloading devices and transmission devices. The main working part of the Gold Mine Machine is a low -speed rotary cylinder that is horizontally installed on the bearings. The tube body is equipped with a grinding body; The load in the static state; the bearing base is the force part of the bearing seat, and the bearing base has the structure of cast steel and the welding structure.

Advantages of Gold Mine mill:

1. Reliable and stable work performance can withstand huge impact loads.

2. The bearings use rolling bearings to reduce the energy loss of the motor by more than 10%, and the bearing is less friction and is not easy to wear.

3. High reliability of the lubrication system has greatly reduced the economic losses caused by the stop.

4. The secret sealing method of the gold mineral ball is reasonable to prevent foreign objects from entering the bearing and avoiding the occurrence of tile accidents.

5. Gold ore grinding machine has strong control and sensitivity. Once the equipment fails, it will automatically alarm and easy to maintain, ensuring the smooth operation of production.

6. The product grinding the gold ore mill is fine and uniform, which can meet the user's high requirements for product quality.

7. During the abrasive grinding process of gold ore, there is less dust and low noise. It will not cause pollution to the environment. It truly achieves low -carbon environmental protection.

The application of gold ore grinding machine in the gold selection and smelting factory:

1. Used for two -stage grinding

Because of the advantages of ultra -fine abrasion, high efficiency, high efficiency, low installation costs, and small wear, etc., it is especially suitable for two -stage mill or ultra -fine mill.

After the transformation, the production capacity reaches 130-140T/d. Production results show that gold ore has low abrasive motor and electrical consumption, high abrasive efficiency, low -loss wear, low vibration noise is less than 85DB.

2. Treatment of sulfur and arsenic -containing gold ore

The gold ore mill has two basic characteristics: ultra -fine abrasive and strengthening chemical immersion. The use of these two characteristics can be treated with certain sulfur and arsenic ore. Using gold ore grinders ultra -fine grinding can strengthen alkaline immersion, which may provide a technically feasible and economic reasonable processing process for some sulfur -containing and arsenic ore -containing gold ore.

3. Ultra -fine mills of gold tail mines are used for secondary utilization

my country has a wealth of gold ore tailings resources. Due to the technical level at that time, in these tailings, especially some gold concentrate tailings, the gold content is as high as 2 ~ 8g/t. The characteristics of these tailings are used for secondary use. Its potential economic benefits are huge, and investment is less and effective.