Ball Mill for Gold Processing: A Key Equipment for Efficient Ore Grinding

Introduction

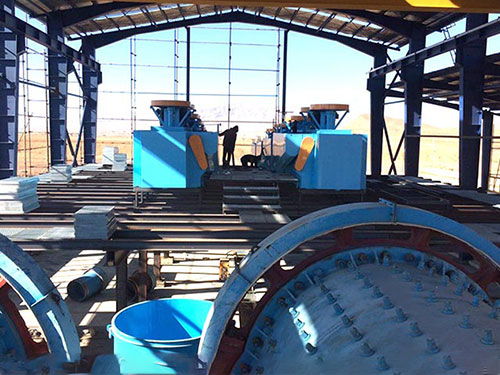

Gold ore processing requires efficient grinding to liberate gold particles from the surrounding rock. One of the most widely used machines in this process is the ball mill, a robust and versatile grinding solution for both small-scale and industrial gold mining operations. This article explores the role of ball mills in gold processing, their working principles, types, advantages, and key considerations for optimal performance.

1. How a Ball Mill Works in Gold Processing

A ball mill is a cylindrical device that rotates to grind gold ore into fine powder. The process involves:

Ore Feeding: Crushed gold ore is fed into the mill along with water (for wet grinding) or air (for dry grinding).

Grinding Media: Steel balls or ceramic beads inside the mill crush and grind the ore through impact and friction.

Discharge: The finely ground slurry (in wet mills) or powder (in dry mills) exits through a discharge grate.

The ground material is then sent to cyanidation, flotation, or gravity separation for gold extraction.

2. Types of Ball Mills Used in Gold Processing

(1) Wet Grinding Ball Mill

Most common in gold processing due to higher efficiency.

Reduces dust and improves gold recovery in leaching circuits.

Suitable for ores with high moisture content.

(2) Dry Grinding Ball Mill

Used in water-scarce regions.

Requires dust control systems.

Less efficient than wet grinding but useful for certain ore types.

(3) Overflow vs. Grate Discharge Ball Mill

Overflow Mill: Simpler design, suitable for fine grinding.

Grate Discharge Mill: Better control over particle size, reduces overgrinding.

(4) Small-Scale vs. Industrial Ball Mills

Small-scale: Used in artisanal gold mining (e.g., 1-5 TPH capacity).

Industrial: Large mills (up to 20+ TPH) for commercial gold plants.

3. Advantages of Using a Ball Mill for Gold Processing

✔ High Efficiency: Consistently grinds ore to the required fineness (typically 75-150 microns for gold leaching).

✔ Versatility: Works with various ore types (free-milling, refractory, sulfide-rich).

✔ Scalability: Available in different sizes for small miners and large-scale operations.

✔ Low Operating Costs: Durable design with minimal maintenance requirements.

✔ Compatibility: Works well with CIL (Carbon-in-Leach) and CIP (Carbon-in-Pulp) gold recovery methods.

4. Key Considerations for Optimal Performance

(1) Grinding Media Selection

Steel Balls: High density, suitable for coarse grinding.

Ceramic Balls: Used for fine grinding and corrosive ores.

(2) Mill Speed & Load

Critical Speed: Typically operated at 65-75% of critical speed for optimal grinding.

Ball Charge: Usually 30-40% of mill volume for efficient impact grinding.

(3) Particle Size Control

Too fine = higher energy consumption.

Too coarse = poor gold recovery.

Ideal range: 75-150 microns for cyanidation.

(4) Maintenance & Wear Protection

Regular inspection of liners and grinding media.

Use rubber or alloy liners to reduce wear.

5. Ball Mill vs. Alternative Gold Grinding Solutions

| Feature | Ball Mill | Stamp Mill | HPGR (High-Pressure Grinding Rolls) |

|---|---|---|---|

| Energy Use | Moderate | High | Low |

| Particle Size | Fine to Ultra-Fine | Coarse to Medium | Controlled |

| Cost | Affordable | Low (but outdated) | High Initial Cost |

| Best For | Most gold ores | Historical use | Hard, abrasive ores |

Conclusion: Ball mills remain the most cost-effective and reliable choice for most gold processing plants.

6. Future Trends in Gold Ore Grinding

Hybrid Systems: Combining ball mills with stirred mills for ultra-fine grinding.

Smart Control: IoT sensors for real-time monitoring of mill performance.

Eco-Friendly Designs: Energy-efficient motors and water recycling in wet mills.

Conclusion

The ball mill is a fundamental piece of equipment in gold processing, offering high efficiency, versatility, and cost-effectiveness. Whether in small-scale mining or large industrial plants, selecting the right type of ball mill and optimizing its operation can significantly improve gold recovery rates.

For miners looking to maximize productivity, investing in a well-designed ball mill system—paired with proper maintenance and grinding media selection—is key to profitable gold extraction.

Looking for a reliable ball mill for your gold processing plant? Contact us today for expert recommendations!